Top 2026 Cooling Tower Innovations You Need to Know?

cooling towers play a crucial role in industrial processes and power generation. They help reject heat from systems, ensuring optimal efficiency. According to the International Energy Agency, cooling accounts for nearly 20% of the world’s energy consumption. Innovations in cooling tower technology can significantly reduce energy use. This presents a dual opportunity: improving sustainability and lowering costs.

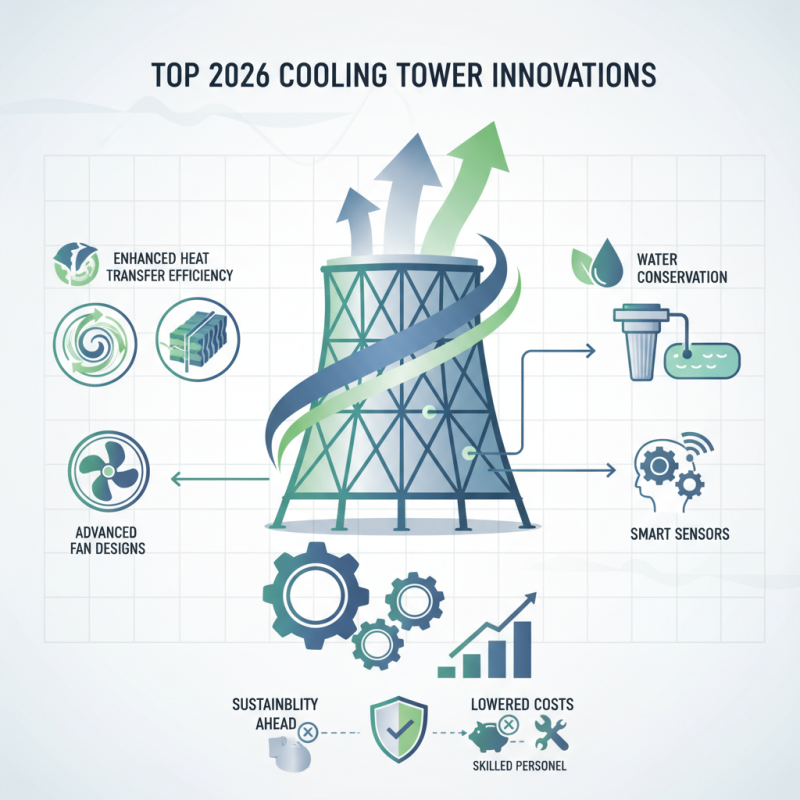

In 2026, advancements in cooling tower design and materials will shape the industry. Emerging technologies are focusing on enhanced heat transfer efficiency and water conservation. For instance, advanced fan designs promise to optimize airflow, while smart sensors can monitor and adjust operations in real-time. However, there are challenges ahead. The integration of new technologies can be expensive and may require skilled personnel for installation and maintenance.

As companies adopt these innovations, they must also reflect on their long-term impact. Effective cooling tower systems must balance performance with environmental considerations. Awareness of these dynamics will be key to future developments in cooling tower technology. The journey toward efficiency and sustainability in cooling towers continues, and understanding upcoming innovations is essential.

Top Innovations in Cooling Tower Design for 2026

As we approach 2026, innovations in cooling tower design are taking center stage. Engineers are focusing on enhancing energy efficiency. Advanced materials are being utilized to reduce corrosion and extend lifespan. These materials allow for greater durability and lower maintenance costs. Imagine a cooling tower that requires less frequent repairs; the impact on operation time is significant.

Another exciting development is the integration of smart technology. Sensors can monitor performance in real-time. When an issue arises, alerts can be sent to operators. This proactive approach helps in preventing potential failures. However, reliance on technology can introduce challenges, like over-dependence. Ensuring a balance between technology and manual oversight is vital.

Sustainability remains key in these innovations. Water conservation strategies are now being implemented effectively. Closed-loop systems minimize water use. Yet, some designs may not achieve optimum efficiency in all climates. Engineers must continue refining these systems. The goal is to design cooling towers that work efficiently in diverse environments.

Energy Efficiency Enhancements in Upcoming Cooling Towers

The future of cooling towers is trending towards enhanced energy efficiency. A report from the U.S. Department of Energy highlights that cooling towers can consume up to 30% of a facility's total energy. This statistic underscores the urgency for innovations in design and operation. Upcoming cooling towers focus on advanced materials and designs that significantly reduce energy consumption. For instance, integrating high-performance insulation can minimize heat losses and optimize cooling cycles.

Moreover, recent advancements include variable speed drive (VSD) pumps and fans. These technologies adapt the cooling output based on real-time load conditions. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers shows that VSDs can lead to energy savings of up to 50%. However, not all facilities leverage these technologies effectively. There can be challenges related to installation and initial costs.

In addition, optimizing water usage is another innovation on the horizon. Efficient water management can reduce operational costs. Many cooling towers evaporate significant water volumes, leading to a loss of resources. Emphasizing dual-purpose designs can help address this issue. Yet, implementing such measures requires careful planning and investment. Some facilities might hesitate due to economic considerations, but the long-term benefits outweigh initial concerns.

Top 2026 Cooling Tower Innovations You Need to Know

| Innovation | Description | Expected Benefits | Implementation Timeline |

|---|---|---|---|

| Smart Monitoring Systems | Real-time data analytics for temperature and fluid levels | Increased operational efficiency and reduced downtime | 2026 |

| High-Efficiency Fill Media | New materials that enhance water evaporation rates | Reduced water and energy consumption | 2025 |

| Modular Cooling Towers | Easily expandable designs for changing cooling loads | Flexibility in installations and maintenance | 2026 |

| Hybrid Cooling Solutions | Combination of wet and dry cooling methods | Optimized performance across varying climates | 2026 |

| Automated Maintenance Alerts | AI-driven notifications for required maintenance | Minimized risks of system failure | 2025 |

Integration of Smart Technology in Cooling Tower Operations

The integration of smart technology in cooling tower operations is transforming the industry. Automation is becoming more prevalent. Sensors now monitor temperature, pressure, and humidity in real-time. This data aids in optimizing performance. It helps to reduce energy consumption significantly.

Predictive maintenance is another exciting innovation. By using machine learning algorithms, towers can predict failures before they happen. This prevents costly downtime. However, reliance on technology raises questions about data privacy. Not every facility has the knowledge to interpret data effectively.

Some cooling towers are now fully automated, responding to environmental changes instantly. While this boosts efficiency, it can lead to potential over-reliance. Operators may overlook manual checks and basic maintenance routines. It's a delicate balance between harnessing technology and maintaining traditional practices. The future may hold even more advanced solutions, but reflection on current practices remains essential.

Top 2026 Cooling Tower Innovations - Integration of Smart Technology

Sustainable Materials and Practices for Modern Cooling Towers

The transition to sustainable materials in cooling towers is gaining traction. Many industries are now exploring eco-friendly options. These materials often include recycled plastics and wood alternatives. They help reduce waste and lower carbon footprints. However, finding the right balance between durability and sustainability is challenging. Some materials may not last as long, leading to increased costs.

Modern cooling towers are adopting innovative practices. Natural cooling methods are now favored over traditional systems. This approach often utilizes ambient air for cooling. However, it requires careful design and planning. Weather conditions can fluctuate unpredictably. These variables pose challenges for consistent performance.

The push for greener practices is essential but sometimes misguided. Not all sustainable choices lead to better efficiency. Some solutions may be cost-prohibitive for smaller facilities. Balancing sustainability with operational needs remains a critical conversation. The journey toward true sustainability is ongoing and full of learning opportunities.

Emerging Trends in Cooling Tower Maintenance and Monitoring

In the realm of cooling tower maintenance, new trends are emerging. Advanced monitoring technologies are paving the way for enhanced efficiency. Sensors now provide real-time data on water quality, flow rates, and temperature levels. This information is crucial for timely interventions and can prevent significant failures.

Regular maintenance can feel like a daunting task. Many facilities struggle with upkeep due to cost or expertise. Operators may overlook small issues, leading to larger problems. Visual inspections often miss hidden deficiencies, which can worsen over time. New digital tools can help bridge this gap. They offer predictive analytics based on historical data to forecast potential failures.

Embracing these innovations requires a mindset shift. Instead of reactive maintenance, a proactive approach can save resources. However, this transition may not be seamless. Many teams may need training to utilize new technologies effectively. It's a process that demands patience and adaptability. As facilities evolve, the importance of consistent monitoring will only grow.