Top 10 Mechanical Parts Suppliers You Should Know?

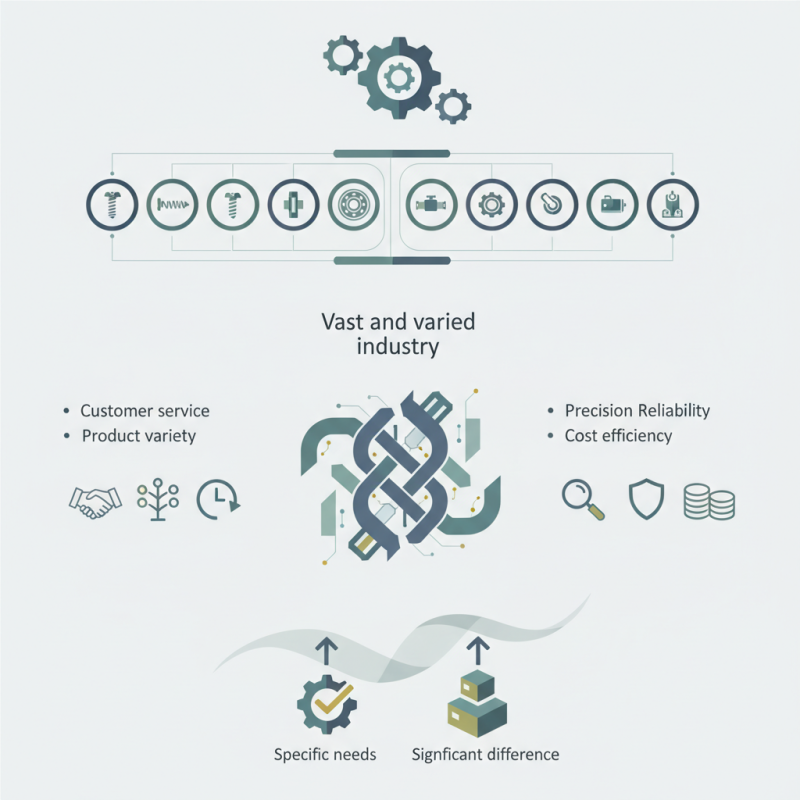

When seeking reliable mechanical parts suppliers, it's essential to choose the right partners. The mechanical parts industry is vast and varied. Each supplier brings unique strengths and weaknesses. Understanding these intricacies can help you make informed decisions.

Many mechanical parts suppliers offer quality products. However, not all are created equal. Some may excel in customer service but lack in product variety. Others might provide a broad range but falter in timely delivery. Identifying the top suppliers is crucial for businesses that depend on precision and reliability.

In this guide, we highlight ten mechanical parts suppliers you should know. Each has distinct features that could influence your choice. Discover which suppliers meet your specific needs. Whether you're looking for cost efficiency or high-quality parts, the right supplier can make a significant difference.

Overview of Mechanical Parts Suppliers in the Industry

The mechanical parts supplier industry thrives on innovation and precision. Many suppliers offer a range of components for various applications. They cater to different sectors like automotive, aerospace, and manufacturing. It's crucial for businesses to understand what they need when selecting a supplier. Reliability and quality often take precedence over cost.

When searching for suppliers, consider their expertise in your specific requirements. Some suppliers may excel in producing precision parts. Others might focus on bulk manufacturing. Ensure the supplier matches your production needs.

Tips: Investigate long-term partnerships. A reliable supplier can drive efficiency. Also, don’t hesitate to ask for sample parts. It’s vital to assess the quality before making large orders. Consider visiting a supplier’s facility. First-hand observations can highlight their capabilities and shortcomings. Always have a backup supplier in mind; flexibility is key.

Criteria for Selecting High-Quality Mechanical Parts Suppliers

Selecting high-quality mechanical parts suppliers is crucial. Companies often rely on rigorous criteria to make these choices. One essential aspect is the supplier's production capabilities. According to a recent industry report, around 70% of businesses prioritize suppliers with advanced manufacturing techniques. This ensures precision and reliability in parts like gears, bearings, and fasteners.

Another critical factor is the supplier's quality control processes. Recent data indicates that companies experience up to a 25% reduction in defects when suppliers implement strict testing protocols. It's not just about meeting minimum standards; proactive quality measures can make a difference.

Furthermore, the relationship between price and value should be carefully considered. Cost-effectiveness matters, but the least expensive options might lack durability or performance. A balance is needed. Many companies report that choosing a slightly more expensive supplier often leads to long-term savings through fewer failures and lower maintenance costs. Always weigh these aspects. It’s easy to get caught up in metrics, but qualitative factors are equally vital.

Top 10 Mechanical Parts Suppliers: A Comprehensive List

When looking for reliable mechanical parts suppliers, it’s essential to consider various factors. Price is critical, but so is quality. A poor-quality part can lead to failures and unnecessary costs. Focus on suppliers who emphasize durability and functionality. Their products should withstand harsh conditions and offer long-term performance.

Tips: Evaluate supplier reviews and feedback. Customer experiences can reveal a lot about reliability. If possible, request samples to inspect the product quality firsthand. Don’t hesitate to ask questions about the manufacturing process. Understanding their sourcing and production methods can give insights into their standards.

Another factor to think about is delivery times. Even the best parts won’t help if they arrive late. Communication with suppliers about lead times is vital. Build relationships with several suppliers to ensure a backup in case of delays.

Tips: Always check for stock availability before placing large orders. Unexpected supply chain issues can disrupt your plans. Be prepared to adapt quickly to avoid setbacks in your projects. No supplier can guarantee perfection; some may experience hiccups. A flexible approach can help you navigate these challenges effectively.

Top 10 Mechanical Parts Suppliers

| Rank | Country | Annual Revenue (Million $) | Number of Employees | Specialization |

|---|---|---|---|---|

| 1 | United States | 5000 | 10000 | Precision Engineering |

| 2 | Germany | 4500 | 8000 | Heavy Machinery |

| 3 | Japan | 6000 | 12000 | Robotics |

| 4 | China | 3000 | 15000 | Manufacturing Components |

| 5 | South Korea | 3500 | 7000 | Automotive Parts |

| 6 | United Kingdom | 4000 | 5000 | Aerospace Components |

| 7 | Italy | 3200 | 4000 | Pneumatic Systems |

| 8 | France | 2700 | 3000 | Electrical Components |

| 9 | Sweden | 2900 | 3500 | Hydraulic Systems |

| 10 | India | 3300 | 5500 | General Manufacturing |

Key Innovations from Leading Mechanical Parts Suppliers

The landscape of mechanical parts suppliers is evolving rapidly. Innovations are driving growth and efficiency in this sector. Many companies are adopting advanced materials. These materials offer enhanced durability and performance. The integration of smart technology is also gaining traction. Sensors embedded in parts can provide real-time data on performance. This information helps companies make informed decisions.

Another key innovation is the focus on sustainability. Eco-friendly materials and processes are becoming standard practice. Many suppliers now prioritize recyclable components. This aligns with global efforts to reduce waste. However, challenges remain. Not all suppliers are keeping pace with these changes. Some still rely on outdated methods. This can hinder their competitiveness in a fast-evolving market.

3D printing technology is another game changer. It allows for the rapid prototyping of parts. This technique reduces time and costs associated with traditional manufacturing. Yet, not every company has embraced this shift. Training staff to use new technologies can be a barrier. Innovation requires a thoughtful approach and a willingness to adapt. Understanding these dynamics is crucial for suppliers aiming for long-term success.

Global Market Trends Impacting Mechanical Parts Supply Chains

Global market trends are significantly reshaping mechanical parts supply chains. Industries face challenges like fluctuating demand and supply shortages. Disruptions can arise from economic shifts and geopolitical tensions. Understanding these trends is essential for businesses. They can no longer rely solely on local suppliers. Global sourcing has become a necessity.

One key trend is the rise of automation and technology. Many companies invest in smart manufacturing techniques. These innovations help optimize production and reduce costs. However, it can lead to a dependency on high-tech components. This introduces risks, especially when suppliers cannot meet quality standards.

Tips: Always evaluate suppliers for reliability and quality. Diversify sourcing options to mitigate risks. Regularly review inventory levels to adapt to changing market demands. Be prepared for unexpected supply chain issues. Flexibility is crucial in today's market. Embrace changes, but also question assumptions. Strengthen relationships with suppliers to enhance cooperation and resilience.